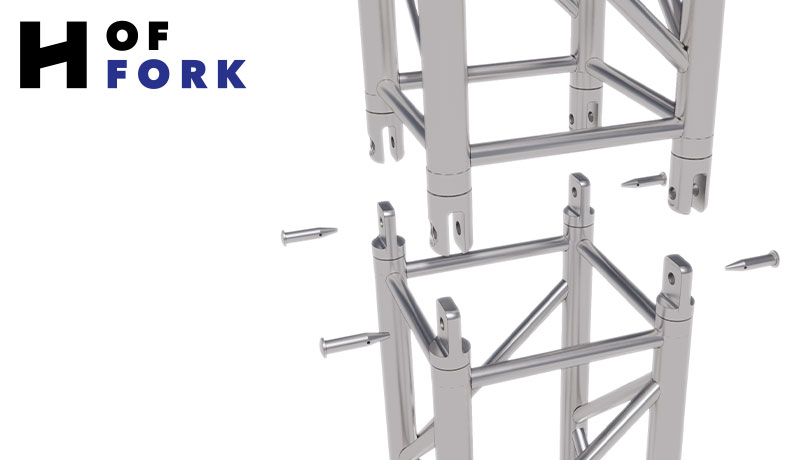

HOFFORK - Fork Connectors

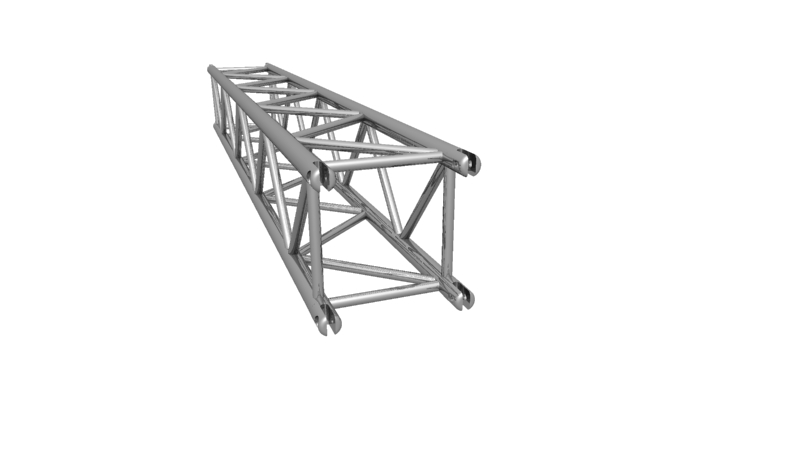

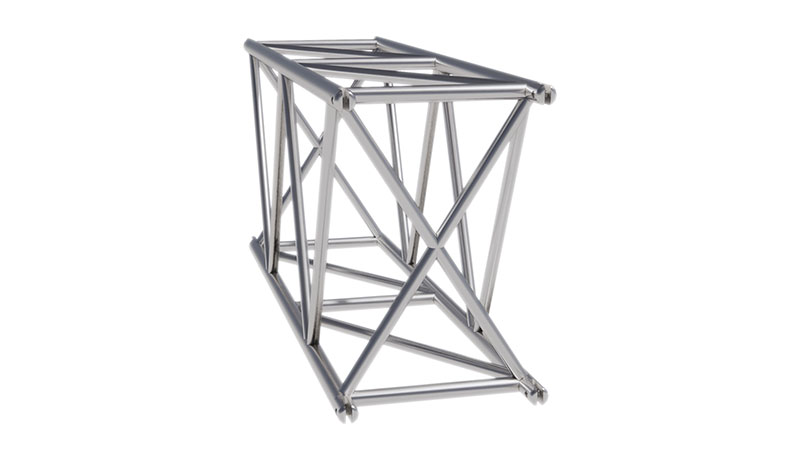

The trusses from the system HOFFORK impress with high load capacity, and also in more comfortable and faster assembly.

The fork connectors welded in the truss can be stuck easily into each other and attach with a pin.

The result is a connection over which even the largest loads can be derived.

Application for this kind of trusses are large stage roofs, large pre rigs, big ground-supports and for all constructions with a maximum wingspan in combination with a maximum payload.